Frame Data -

Clips

(Revised: 08/10/2023)

The Clips tab is used to Insert, Revise, or

Delete the Bolted or Welded Clips on Frames.

This tab allows you to modify multiple wall or roof sides at any time.

It is possible to insert Clips into a member prior to frame design and

detailing.

The options for clips will vary depending on

the detail selected, this tab will automatically enable the appropriate options

for each clip detail.

The locations of the clips are measured from

the floor line along walls and from the ridge or high side on rafters.

Refer to: Frame Data - Work Points

Sample

Options - Clips:

|

Welded Clips - Flange |

Turned Welded Clips - Flange |

Bolted Clips - Flange Automatically adds

Flange holes. |

|

Welded Clips - Web |

Turned Welded Clips - Web |

Bolted Clips - Web Automatically adds Web

holes. |

List:

This list box contains the Clips on the

selected Frame Column(s) or Rafter(s).

The

list will indicate the unique conditions if multiple columns or rafters are

selected with different Clip criteria.

|

|

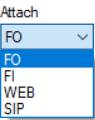

„ How to Use: This list will only display the

Clips Attached to the selected Web, Flange, or Single Plate (bolting plate). Clips Attached to FO = Displays

only the Clips Attached to the Outside Flange. Clips Attached to FI = Displays

only the Clips Attached to the Inside Flange. Clips Attached to Web = Displays

only the Clips Attached to the Web. Clips Attached to SIP = Displays

only Clips Attached to a SIngle Plate. |

Options:

Along

(Read only)

The

Along drop list describes the flange that the measurements are defined along.

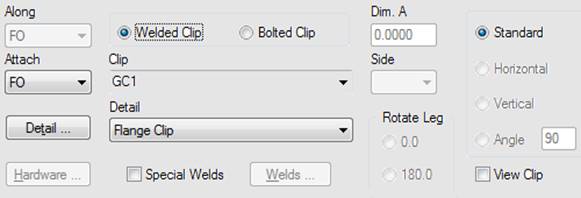

Welded Clip /

Bolted Clip

These

radio buttons set the available clip details and types to the valid Welded or

Bolted Clip.

This

also controls the Clip Mark Number drop list; only valid clip mark numbers will

be in the list.

Dimension A

This edit box is used to define special distances required

for some Clips

Attach

The

Attach drop list describes the flange, web, or plate to which the clip is welded

or bolted.

Clip Drop

List

This

dropdown list contains the valid part numbers dependent on the clip type.

The values in the list box can be edited for clips that require variable

dimensions.

Side

This

drop list is used with clips located on a web.

The

Near Side of a column is the side closest to you when the flange outside is on

the right.

The

Near Side of a rafter is the side closest to you when the high side is on the

right.

Refer

to: Near Side

and Far Side

Detail Button

This

button will display the Detail options, if a detail is selected from the

options pictured, it will automatically update the Detail drop list.

Each

detail indicates how the clip is located.

Refer

to these Details for dimensioning clarity. Including: Orientation, Dim A, and

Angle.

Detail Drop

List

This

drop list allows you to select the Detail without having to use the selection

options from the Detail button.

.

Clip Orientation:

The Orientation radio buttons allows you to manipulate the clip's

direction.

Standard

The Standard orientation option will default to

the most common use of the clip as shown on the Clip's Detail.

Horizontal

The Horizontal option will force the clip's

orientation to be parallel to the ground.

Note: Manufacturing documentation will be

translated to an Angled dimension.

Vertical

The Vertical option will force the clip's

orientation to be perpendicular to the ground.

Note: Manufacturing documentation will be

translated to an Angled dimension.

Angle /

Value

The Angle option allows you to define the angle

of the clip from the flange or web.

This edit box defines the angle of the clip in

degrees.

Rotate Leg:

Rotate Leg -

0.0 or 180 degrees

0.0

orientates

the bent leg of a clip toward the work point.

180.0

orientates the bent leg of a clip away from the work point.

Refer

to the Details for dimensioning clarity.

Miscellaneous:

Hardware

Button

This

button will display the Hardware options for the Clip attachment.

Special Welds

This

checkbox enables the Welds Button allowing you to define Special Weld for the

Clip attachment.

Welds Button

This

button will display the Special Weld options for the Clip attachment.

Standard

Weld shown on the Manufacturing Reference Details will be used if this option

is not selected and defined.

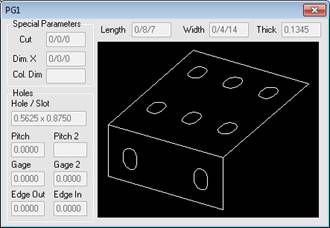

View Clip

Selecting

this checkbox will display a pop-up screen of any Clip in the list, after it is

selected.

This

is for reference only.

Holes, Clips, Stiffeners, Flange Braces,

Brackets, & Misc Clips Locations

(The method

used to locate parts on a frame side is the same on all Frame Data tabs.)

Location:

Based on the radio button option selected, the location options will be

enabled or disabled as required.

Radio Button

Options

End 1 / End

2

These radio buttons set the measurement method

along the Wall Side (building line / girt line) or the Roof Side (roof line /

purlin line). End 1 on a Wall Side are measured from the Finished Floor

Elevation, a positive dimension is upward. End 1 on a Roof Side is from the

ridge (or high side), a positive dimension is down-slope (along the slope). End 2 is measured from the low eave.

Member

This option sets the measurement method along a

Designed Frame Member. The locations along a column member are measured from

the lowest point of the member (along the outside flange) inside any applicable

base plate or splice plate, a positive dimension is upward. The Locations along

a rafter member are from the highest point (along the outside flange) inside

any applicable splice plate, a positive dimension is down-slope (along the

slope). The measurement options will be enabled or disabled as required.

Note: This option is not available if the

frames have not been designed.

Horizontal

This option sets the measurement method

parallel to the floor. This enables the location to be a horizontal dimension

from the work point.

Note: This option is only available on rafters.

Vertical

The option sets the measurement method

perpendicular to the floor, measured from the Finished Floor Elevation.

Note: This option is only available on columns.

X and Y

The X and Y radio button

sets the measurement method of locating stiffeners using a 2D coordinate value,

from the work point. The measurement options will be enabled or disabled as

required.

„

How to use:

On rafters,

the X coordinate will be a negative dimension down from the work point (ridge

point or high eave point) at the sheet line.

This option

is intended for use on webs, though it can also be used on a flange if desired.

„

How to use:

Comparing the

usage of all radio button options:

"End 1" is used most frequently.

Location

Total

Distance (read only)

This displays the overall length of the Wall

Side or Roof Side selected. If multiple columns or rafters are selected with

varying lengths, this box will not display a length.

Quantity of

Spaces / Spaces At

This edit box is used to insert multiple

locations into the list. It is used in conjunction with the Spaces At edit box.

You can insert into the middle of the existing

list by selecting a row in the list prior to entering the location information.

The locations will be added prior to the row selected without moving the active

row.

This edit box defines the distance between the

locations inserted into the list. Inserting new rows is used in conjunction

with the Quantity of Spaces edit box. Revising a Space will automatically

adjust all of the following spaces to new locations.

Location At

This edit box is used to insert or revise a

specific location in the list. Locations will be added or modified in the list

without moving any other row.

You can insert into the middle of the existing

list without selecting a row from the list.

„

How to use:

Comparing the

usage of both locating methods "Spaces At" & "Location

At": "Location At" is

used most frequently.

Location - X

/ Y

The X - Y work points for columns is at the base and at the ridge or

high side for rafters.

X

Horizontal

This edit box displays the horizontal dimension

from the work point.

Note: On rafters, the X coordinate will be a

negative dimension down from the work point (ridge point or high eave point) at

the sheet line.

Y Vertical

This edit box displays the vertical dimension

from the work point.

Location -

Member

Flange

Length (read only)

This box is the length

of the designed Member's Flange not including bolting plates.

Member

ID

This drop list displays

the names of the designed Frame Members. The list includes all

of the Members along the Frame Line.

Location

At

This edit box is the

dimension from the edge of the designed Member's Flange not including bolting plates.

Options:

Insert,

Revise, Delete, and Delete All

These

buttons add, modify, & remove row(s) of data into the list.

Standard

Controls:

See also: