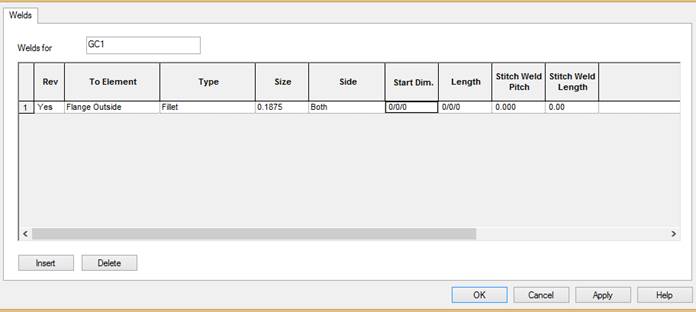

Frame Data & Frame Member Data – Special Welds

(Revised: 10/27/2015)

The Weld tab is used to Insert, Revise, or Delete

the weld on Frame Members.

The Design Engineer should provide

any non-standard weld requirements.

However, at any time, Remarks

can be added to Welds to help the shop in fabrication.

Options:

Welds for

(Read only)

Displays

the part that is being welded onto the frame.

To Element

This

drop list contains the elements (Flanges, Webs, Plates, Clips, Stiffeners…)

that the selected part can be welded to.

„

How to use:

If the selected part is going to be

welded to more than 1 Elements, each weld should be entered into the list

separately.

Type

From

the drop down list select the required weld type

(Fillet, Full Penetration, Partial Penetration).

„

How to use:

When revising extended bolting plates to

flush, 2 sided Fillet Welds need to be revised to a Full Penetration Weld.

Size

From

the drop down list select the required weld size.

„

How to use:

Full Penetration Welds and Partial

Penetration Welds default to 99.

Side

From

the drop down list select the required side(s) to be welded (Both Sides or One

Side).

Start Dim.

& Length

In

these edit boxes, insert the Start Dim which is where the weld is to start from

end 1 of the part. The length is how

long the weld is to be.

„

How to use:

Ex. – Start Dim.

= 0/2/0, Length = 0/4/0. Weld will start

2” in from End 1 and will be 4” long.

Pitch & Length

In

these edit boxes, insert the pitch and length of staggered welds, if required.

Notes

In this

edit box insert any additional remarks that are necessary for the required

weld.

„

How to use:

The remarks can be used to add weld

notes to aid the shop in positioning of a clip or define the orientation.

When locating an -SP- or -XP- clip, use

Remarks to get the correct orientation such as: ‘Locate REF SIDE Toward Flange

Inside’.

Refer to: Frame - Standard Weld Notes

Insert and Delete

These

buttons add, modify, & removes row(s) of data into the list.

List

This list box contains the special welds required for the

attachment of the selected part to the frame member.

Standard

Controls:

See also:

Weld Symbols: