General Information -

(Revised: 10/11/2023)

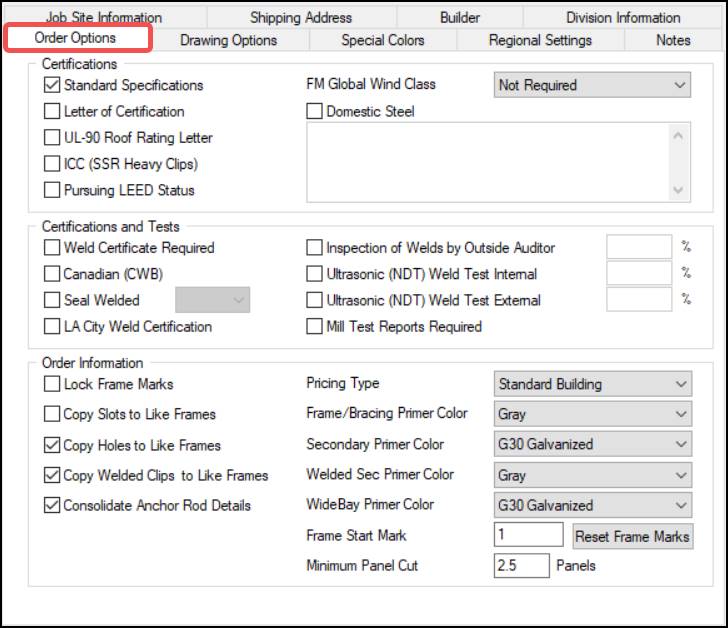

Order

Options

The Order Options tab is used to identify building

Certifications, Material Certifications and Tests, and Order Information. A

default file can be created to auto-fill this

information. The system defaults are shown.

Certifications:

Standard Specifications

Click

on this box if the Metal Building Manufacturer's Standard Specifications can be

used.

If

this box is not checked, submit, and clearly define the specifications that

must be adhered to on this project.

Letter of Certification

Click

on this box if a Letter of Certification is required.

UL-90 Roof Rating Letter

Click

on this box if a UL 90 Roof Rating Letter is required.

If selected on a job with SSR, the Trim Kits will supply SSR Heavy Clips.

ICC (SSR Heavy Clips)

ICC

is for Ordering Reference Only.

If ICC (SSR Heavy Clips) is selected for an SSR job, the Trim Kits will supply

SSR Heavy Clips.

Pursuing LEED Status

If applicable, indicate if the building is to be LEED-certified.

FM Global Wind Class

This

is for Ordering Reference Only, Design for FM is not automated and will require

a quote/estimate.

If selected for a job with SSR, the Trim Kits will detail for FM and supply SSR

Heavy Clips.

Domestic Steel

If applicable, enter if domestic steel is required

for the project and list the requirements that must be met.

·

Projects with Domestic Steel

Requirements must be custom quoted by the Region. BBNA cannot

comply if 100% Domestic Steel is required. Please send specific requirements

(such as BAA, STAA, AIS, etc..) to the Region for review and to complete the

custom quote process.

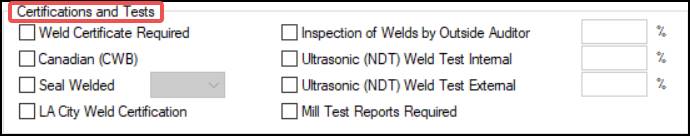

Certifications and Tests:

Weld Certificate Required

Select if a welding certificate is required. This may be indicated in the project specifications.

Canadian (CWB)

Required for all orders shipping to Canada. (CWB = Canadian Welding Bureau)

Seal Welded

Typical for hot-dipped

galvanized parts. Select the class of galvanizing.

Class I - Details are those consisting of parts that are

joined together by a full seal weld, or parts which are bolted together after

galvanizing. This class represents the highest degree of corrosion protection

attainable but requires more fabrication cost.

Class II - Details are those consisting of overlapping parts

that are joined together by seal welding and have an overlapping area that is

large enough to need venting following guidelines. A very high degree of

corrosion protection is available with these details, although not quite equal

to Class 1. Additional fabrication costs are about the same as Class I since

the only difference is that Class I requires plugging vent holes and touching

up the bare metal after galvanizing, whereas Class II does not.

Class III - Details do not include seal welding, which does not

involve more fabrication effort than normally employed on a non-galvanized

structure. Class III details enable the galvanizing to provide a degree of

corrosion protection that meets or exceeds the protection provided by most

industrial coatings.

LA City Weld Certification

Required for welded parts

being erected in the city of Los Angeles, California.

Inspection of Welds by

Outside Auditor

Select if an outside auditor

is required. Typically indicated in project specifications.

Ultrasonic (NDT) Weld Test

Internal

Select if required, typically

indicated in project specifications. (NDT) = Non-Destructive Testing.

Ultrasonic (NDT) Weld Test

External

Select if required, typically

indicated in project specifications. (NDT) = Non-Destructive Testing.

Mill Test Reports Required

Select if required, typically

indicated in project specifications.

Order Information:

The system defaults are shown.

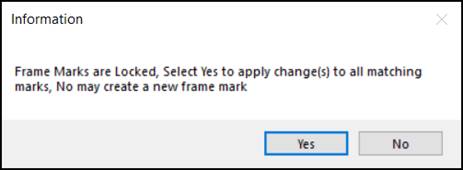

Lock Frame Marks

When

selected, this feature will display a warning when changes are made to an

assembly. Choose Yes or No to control how part marks are assigned. This feature

must be manually activated.

Copy Slots to Like Frames

This

will not be checked by default, Slots may be copied to all “Like” parts to

reduce Frame Mark Numbers.

If selected, deleting or revising Slots in Frame Data may result in the Slot

being re-detailed in the original copied location.

Web

Slot Tolerance >= 6"

Note: There are additional limitations to what can be automatically copied.

Copy Holes to Like Frames

This

will be checked by default, Holes may be copied to all “Like” parts to reduce

Frame Mark Numbers.

If selected, deleting or revising Holes in Frame Data may result in the Hole

being re-detailed in the original copied location.

Flange Hole Tolerance >= 2"

Web Hole Tolerance >= 6"

Note: There are additional limitations to what can be automatically copied.

Copy Welded Clips to Like

Frames

This

will be checked by default, Welded Clips may be copied to all “Like” parts to

reduce Frame Mark Numbers.

If selected, deleting or revising Welded Clips in Frame Data may result in the

Clip being re-detailed in the original copied location.

Flange Clip Tolerance >= 6"

Web Clip Tolerance >= 6"

Note:

There are additional limitations to what can be automatically copied.

Consolidate Anchor Rod

Details

This

will be checked by default. This allows for all common details to be grouped

with a naming convention that is descriptive enough to understand easily, but

all dimensions still need to be read from the details page.

Pricing Type

This

is used for Pricing levels, based on the Type.

Sample: Standard Building or Fast-Track

Frame/Bracing Primer Color

Select

to change the Primer Color for all Frames, Bracing, Ship Loose Clips, and

Flange Braces.

Secondary Primer Color

Select

the Primer Color for all Secondary Zee's, Cee's.

Welded Secondary Primer

Color

Select

the Primer Color for all Secondary Jambs, Headers, Eave Purlins.

WideBay/Truss Purlin XT

Primer Color

Select

the Primer Color for roof secondary structural Truss.

Frame Start Mark

Input

the starting mark number for the frames to start counting at.

This

is usually used when Phasing a project, so the frames

for each phase will have different frame numbers so they will not be confused

on the jobsite.

·

1 – 999 can be entered.

·

Reset Frame Marks button must be pushed to update the Mark Numbers.

o

This can also be used to update and consolidate the mark numbers without

changing the value in the input box.

Minimum Panel Cut [ ] Panels

Indicate

the number of panels that need to be within an opening before they are cut

(removed).

If

the number of panels inside an opening is less than this number, the opening

will be sheeted over.

·

Default value is 2.5.

Standard

Controls:

See also:

§ General Information - Job

Site Information

§ General Information -

Shipping Address

§ General Information -

Builder

§ General Information -

Division Information

§ General Information - Drawing

Options

§ General Information -

Special Colors