User Clips

(Revised: 02/24/2021)

The User Clip screen defines

special Clips and Plates that are required for the job but do not match any

standard Fabrication Reference Drawing.

Clip /

Plate Mark Numbers:

SP

Clips/Plates:

Must be Flat (no bends) and also

must be Rectangular.

Holes can be added through Vision to SP Clips/Plates.

„

How to use:

SP Clips/Plates are to be defined on

this page.

Do not alter them

using exception drawings.

Exception drawing

can be used to locate the clip, if needed.

Hip or Valley Clips can also be created on this screen (see

below).

XP

& CPSX Clips

Clips can be defined on this screen to enable the location of

the part.

CPSX clips are welded assemblies with sub

units.

XP type clip is to be used if:

Clip has more than one bend.

Piece in flat is not a

rectangular shape.

Holes cannot be added through Vision for XP, CPSX Clips/Plates.

Material cannot be defined on CPSX input screen.

„

How to use:

Exception Drawing required for the

following:

XP - Flat Clips /

Plates (Shop Weld or Ship Loose)

CPSX - Welded

Assembly (Ship Loose)

SB Clips

These clips have a single

bend.

Holes can be added through

Vision for SB clips.

„

How to use:

Drawing will be generated for:

SB

– Single bend clip (Shop Weld or Ship Loose)

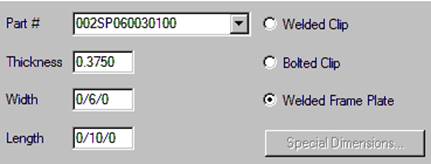

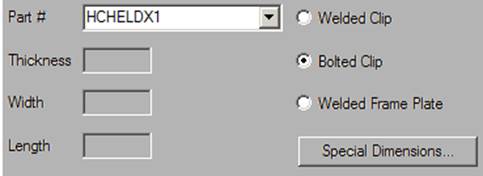

Clip / Plate Input:

Welded

Clip

„

How to use:

The Clip defined on this screen will

be available for selection in:

Frame Data -

Clips - Welded Clips.

User Gage –

Welded Subparts

User Angle –

Welded Subparts

Available clips – SB, SP, XP.

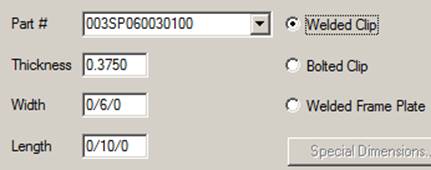

Bolted

Clip

„

How to use:

The

Clip defined on this screen will be available for selection in:

Frame Data -

Clips - Bolted Clips.

User Gage – Welded

Subparts

User Angle –

Welded Subparts

Warehouse – as a

Ship Loose Clip

Available clips – SB, SP, XP, CPSX,

HC__, VC__.

Welded

Frame Plate

„ How to use:

The Clip defined on this screen will be available

for selection in:

Frame Member Data

- Bolting Plates.

User Gage –

Welded Subparts

User Angle –

Welded Subparts

Available plates – SP, XP

Length,

Width, Thickness

Input in these boxes will

automatically update the Mark Number.

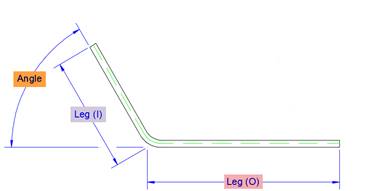

Angle,

Leg (O), Leg (I) - (SB Clip Only)

These boxes appear when SB clip is chosen.

Angle – Input angle of break. Not the finished (included) angle.

Leg (O) – Input leg length at Out end

of clip. This is finished leg length (leg length after angle is formed).

Leg (I) will be calculated

when dimension is input for Leg (O).

Leg (I) – Input leg length at In

end of clip. This is finished leg length (leg length after angle is formed).

Leg (O)

will be calculated when dimension is input for Leg (I).

Part Length will be

determined by the lengths input in Leg (O) and Leg (I).

„

How to use:

To activate these boxes after selecting

the Base Mark Number, you will need to press the TAB key or Apply or any of the

Radio Buttons (Welded, Bolted, Frame Plate).

Holes / Slots Location List:

All holes and slots entered

will be located on the SP Drawing in Manufacturing.

Holes / Slots can be inserted & revised directly in this list.

„

How to use:

Length is used to

define the length of a Slot. Angle will rotate the slots.

Selecting a row

will also highlight the hole/slot in yellow.

„

Warning:

Minimum Edge

Distances are not checked by the software on SP Plates.

Try not to

duplicate locations in the Holes/ Slots Locations List.

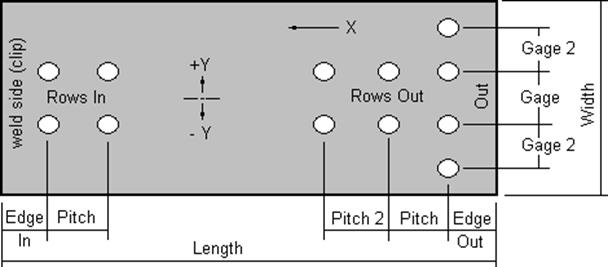

Insert Standard Holes:

Using the Insert Standard

Holes option quickly can enter many holes into a plate (symmetrical about the

width +Y, -Y).

Holes can be input for SP & SB plates/clips.

„

How to use:

After filling in

the desired hole information, select the Inset Std Holes Button.

These holes locations

and sizes will be added to the bottom of the Hole/Slot Location List.

If the result is

not what is needed, you can delete all holes in the list and repeat the

previous steps.

Welded Clip & Bolted Clip (Frame Data):

Locate the Welded or Bolted

Clip after creating it in the User Clips using the Frame Data screen.

„

How to use:

First Refresh the Tree

"F5".

Go to the Frame Data - Frame Side -

Clips screen.

Select the appropriate Welded Clip

or Bolted Clip Radio button.

Locate the Part list and select the

User Clip that you created.

Bolted Clip drawings will print with the Manufacturing Build,

however it will not be available in FSD.

Welded Clip drawings will print with

the Manufacturing Build in FSD after the Frame Part that it is welded to.

Welded Frame Plate (Frame Member Data):

Locate the Welded Frame

Plate after creating it in the User Clips using the Frame Member Data screen.

„

How to use:

First Refresh the Tree

"F5".

Go to the Frame Member Data -

Properties - Plates screen.

Select the Part No and select the

User Clip that you created.

Plate drawings will print with the Manufacturing Build in FSD after the Frame

Part that it is welded to.

Bolted Clip (Warehouse):

Locate the Bolted Clip after

creating it in the User Clips using the Warehouse screen.

„

How to use:

First Refresh the Tree

"F5".

Go to any Warehouse Parts screen.

Select the Category of Clip Member.

Select the Part list and select the

User Clip that you created.

The plate drawing will print with

the Manufacturing Build, however it will not be

available in FSD.

Hip & Valley Clips HC_X & VC_X:

Hip and Valley Clips are typically

created by the software on the Building when required.

If special Hip or Valley Clips are required that could not be generated

correctly by the software, this feature can be used.

Select Bolted

Clip radio button.

When the Hip or

Valley Clip is selected from the Part # drop down list the Special Dimensions

button will be enabled.

Input

Parameters

Define the clip conditions that are required for the special condition.

The default Flange Width for clips generated on a building is 12".

Output

The Work Point, Cutback, and Flashing dimensions are disabled and are

for reference only.

The Clip Dimensions refer back to a Fabrication

Drawing, these dimensions can be revised on this screen if required.

„

Warning:

If you return to a

Hip / Valley Clip that has already been created, the Final Dimensions are per

the original input and any possible Dimension revisions.

All other information

has returned back to a default, the software does not

retain the original input Parameters.

Bent Clip (SB):

„

How to use:

The SB clip can be input as a Welded

Clip or a Bolted Clip.

Select an SB clip from Part # drop

down.

Adjust thickness & width as

required (thickness in part mark is shown in sixteenths).

Length will be calculated from Leg

(O) & Leg (I) input or part mark.

Enter the angle of the break. Not

the finished (included) angle.

Input the Leg (O) & Leg (I)

lengths as the lengths of the angle legs after it is formed.

„

Note:

The

bend allowance is calculated when parts are imported into PIM and will not be

reflected on this screen.

Standard

Controls:

See also: