Frames – Standard Weld Notes & Ref Details

(Revised:

03/19/13)

These Lessons are to standardize the Weld Notes and Reference Details that are

being used to locate Special

Clips/Stiffeners/Brackets.

In order to help the welders better interpret weld notes, the

following Weld Notes and Reference Details should be

used.

|

Recommended

Standard Weld Notes |

|

Clips |

|

**

(Clip to Hole

Dimension = __) |

|

**

(Web to Hole

Dimension = __) |

|

**

(Center Between Holes) |

|

** (Locate

OUT Toward) |

|

** (Locate

OUT Toward End 2) |

|

** (Locate With REF SIDE Away from __) |

|

**

(Locate With REF SIDE Toward __) |

|

**

(Weld REF SIDE 2 to __) |

|

**

(Weld REF SIDE to __) |

|

(Weld

__” Side to Web) |

|

**

(Lay Flat on Web

& Weld All Around) |

|

** (Opposite Conrac at Clip +

3 in. past) |

|

**

(Do Not Paint MZ Clip in Optional Paint Zone) |

|

**

(Do Not Paint Clip 4

in. from OUT of

Clip) |

|

**

(Do Not Paint __) |

|

** (Do Not

Paint Both Sides of Clip) |

|

(Do

Not Paint UCC

Clip) |

|

**

(Offset Flange Clip __

Toward Far Side) |

|

**

(Offset Flange Clip __

Toward Near Side) |

|

**

(Verify Cut on MZ Clip = __) |

|

(Locate

With WELD SIDE to Web) |

|

** (See

Exception Drawing for Location/Welds) |

|

(Turn Clip w/ Hole Away from End __) |

|

|

|

Stiffeners |

|

(Hold

S4 Stiffener 2” Clear from Cut In Plate) |

|

|

|

Plates

(Splice PL / Cut In PL / Scab On PL) |

|

**

(At Hole Groups + __

Past - Use Min Weld Between Hole Groups per WS-P-01) |

|

**

(At Hole Groups + 3 in. Past) |

|

** (At Hole Groups + 3 in. Past - Located in

the __ at __) |

|

**

(Between Hole Groups) |

|

** (Weld web 6 in. past

plate) |

|

(Offset

Plate __” Toward Near Side - Locate with “Rows” Toward Near Side) |

|

|

|

Brackets

/ Beams |

|

**

(Do Not Paint Both Sides of Bracket from 9” from End 2 of Bracket) |

|

**

(Do Not Paint Both Sides of Web for __ from End __ of Beam) |

|

** (Opposite

Conrac at Bracket + 3

in. past) |

|

** (Opposite

Conrac Starting at __) |

|

|

|

Auto

Welds |

|

**

(FI Auto Weld) |

|

**

(FO Auto Weld) |

|

|

|

These

are Some Recommended Weld Notes, Other Weld Notes May Apply. **

Indicates a Preset Weld Note at:

|

|

System

Generated Weld Notes |

|

Clips |

|

(Do Not

Paint MZ Clip in optional paint Zone) |

|

(Do Not Paint Clip 4 in. From OUT of Clip) |

|

(Locate

With WELD SIDE to Web) |

|

(Locate

REF SIDE Away from Flange) |

|

(Locate

OUT of clip toward End2 of column) |

|

(This

weld is Opposite Conrac Web Weld at KBC clip. Make weld length equal to clip

weld side) |

|

|

|

Plates

(Splice PL / Cut In PL / Scab On PL) |

|

(Weld

web 6 inches past plate) |

|

|

|

Rules

for Generating Weld Notes Requested

from manufacturing. |

|

·

Try not to make Weld Notes too long. |

|

·

If the Weld note is to replace an FSD

Dimension, Make a note of it. (Use Dim A = 4” in place of FSD Dim A) |

|

·

If an Exception Drawing is required,

use a Weld note to explain what the Exception is for. (See Exception Drawing for Location/Welds/Etc…) |

|

·

Keep in mind that Small Parts Does NOT

mark the OUT or WELD SIDE of standard parts on the plates. Try not to use

these when locating clips with weld notes. |

|

·

If inserting user input auto weld

notes, capitalize the first letter of Auto and Weld. |

Angle Brace Connection @ Eave Strut with

Special Plate (-SP-)

|

|

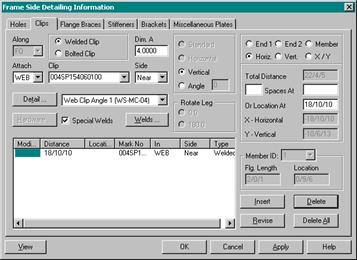

1.

Create the -SP- Plate with the “Weld Side” to

Web and the “Ref

Side” toward Finish Floor. 2.

Use a "Web Clip Angle 1 (WS-MC-04)" clip detail. Locate the

Clip Horizontal along the Roof. With the Angle as Vertical, and Dim A to the

First Hole for the Brace Strut.

3.

Add a weld note to the FO weld as "Locate

REF SIDE Away from Flange". 4.

Another weld note for Slip Critical Connections may be

required, add this weld note to the FO weld as "Do Not Paint Clip 4 in. From OUT of Clip". 5.

The SP Plate will automatically generate a note on the Weld

Side as “Weld to Web”. No additional notes are req’d

for the Weld Side. |

Angle Brace Connection @ Intermediate Strut

with Special Plate (-SP-)

|

|

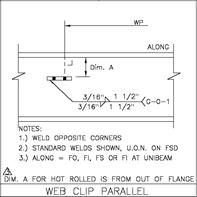

1.

Create the -SP- Plate with the “Weld Side” to

Web and the “Ref

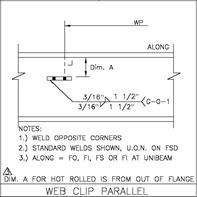

Side” to Strut Clip. 2.

Use the “Web Clip Parallel (WS-MC-04)” clip detail.

3.

Add a weld note to the Clip weld as "Locate with REF SIDE to Web Clip Adjacent". 4.

An optional weld note to the Clip as "Center Between Holes" can be used, but is NOT

required. 5.

The SP Plate will automatically generate a note on the Weld

Side as “Weld to Web”. No additional notes are req’d

for the Weld Side. |

Rod Connection

to BP with Standard Plate (RWB-)

|

|

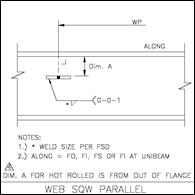

1. Use

the “Web

SQW Parallel (WS-MC-05)” clip detail.

2. Note

that the Dim A is from the Inside of Flange. 3. An

optional weld note to the Web weld as "Web to Hole Dimension = ___” can

be used. 4.

An optional weld note to the Base Plate as "Center Between Holes" can be used, but is NOT

required. |

Angle Brace Connection to BP with Special

Plate (-SP-)

|

|

1. Create

the -SP- Plate with the “Weld

Side” to Web and the “Ref Side” to Base Plate. 2. Use

the “Web

Clip Parallel (WS-MC-04)” clip detail.

3.

Add a weld note to the Base Plate weld as "Locate With REF SIDE to End Plate". 4. An optional

weld note to the Base Plate as "Center Between

Holes" can be used, but is NOT required. 5. The

SP Plate will automatically generate a note on the Weld Side as “Weld to

Web”. No additional notes are req’d for the Weld

Side. |

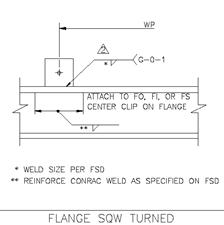

Rod Brace Plates

(RWB) on Strut Beam Flange

|

|

1. Use

the “Flange

SQW Turned (WS-MC-02)” clip detail. 2. To

help with the Plate Rotation we will need to add the Weld Length to the Flange

Weld Information as the length of the RWB side that is to be welded to the

flange.

3. Add

a weld note to the Flange weld as "Turn

Clip w/ Hole Away from End 1" or "Turn Clip w/ Hole Away from End 2". 4. Add

a Weld Note for an Opposite Conrac Weld if Required. Insert a Weld to Web

with the Opp Conrac weld size and add a Note as "Opp Conrac at Clip + 3” past". |

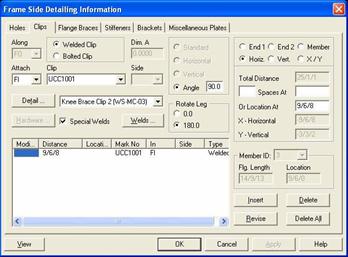

Flange Clip on Rafter Inside

Flange (Clip With Cut)

|

|

1. Use

the “Knee

Brace Clip 2 (WS-MC-03)” clip detail. 2. Locate

the Clip Horizontal from Ridge or High side to the Longest (Edge) of the Clip. 3. Insert

Clip with a Rotation of Rotate = 0 (Toward End 1) Rotate = 180 (Toward End 2) 4. Add

a Weld Note for an Opposite Conrac Weld if Required. Insert a Weld to Web

with the Opp Conrac weld size and add a Note as "Opp Conrac at Clip + 3” past". |

|

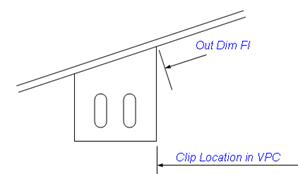

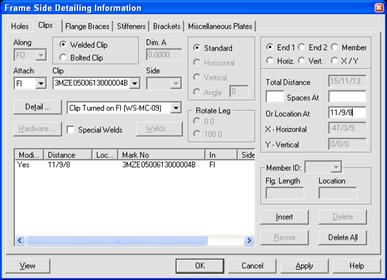

Explanation

Why Standard “Clip Turned on FI (WS-MC-09)” will Not work on a Rafter Flange. |

|

|

|

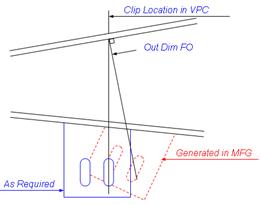

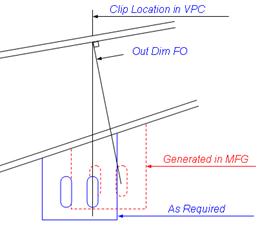

If the Clip Turned on FI

(WS-MC-09) Detail (with the Out Dim FO to the Hole) is used the Clip will be

fabricated incorrectly. This Detail does not allow for specifying the

orientation of the clip. Some tapered sections may get deeper progressing from

end1 and some may get shallower progressing from end1. The direction of taper

requires the clip to be flipped 180 degrees. When you insert the Clip

horizontal the system will generate an Out Dim FO on the FSD. The Shop will

locate the Out Dim FO with the Hole 90 degrees from

the flange outside and the clip will be not be located correctly. |

Flange Clip on Tapered Inside Flange (Clip With Cut)

|

|

1. Use

the “Clip

Turned on FI (WS-MC-09)” clip detail. 2. Locate

the Clip along the FO to the First Hole of the Clip. 3. Add

a Weld Note for an Opposite Conrac Weld if Required. Insert a Weld to Web

with the Opp Conrac weld size and add a Note as

"Opp

Conrac at Clip + 3”

past". 4. An

optional weld note to the FI weld as "Locate

OUT toward End2"

can be used, but is NOT required. |

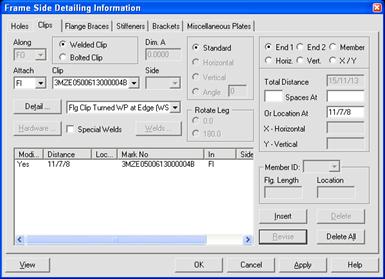

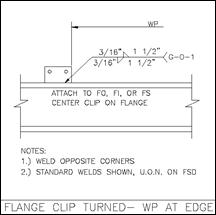

Flange Clip on Tapered Inside Flange (Clip

w/o Cut)

|

|

1.

Use the “Flange

Clip Turned - WP at Edge (WS-MC-08)” clip detail. 2.

Locate the Clip

along the FO to the Bottom (Edge) of the

Clip. This will generate the Out Dim FI along the FI to the Bottom

(Edge) of the Clip. 3.

Add a Weld Note for

an Opposite Conrac Weld if Required. Insert a Weld to Web with the Opp Conrac weld size and add a Note as "Opp Conrac at Clip + 3” past". |

|

Explanation Why

Standard “Flange Clip Turned (WS-MC-01)” with the Out Dim FI to

the Hole will Not work on a Tapered Flange. |

|

|

|

If

the Flange

Clip Turned (WS-MC-01) Detail (with the Out Dim FI

to the Hole) is used the Clip will be fabricated

incorrectly. The detail does not allow for Taper on the Flange Inside. When

you insert the Clip the system will generate an Out Dim FI on the FSD. The

Shop will locate the Out Dim FI with the Hole 90 degrees from the flange and

the clip will be dropped. |

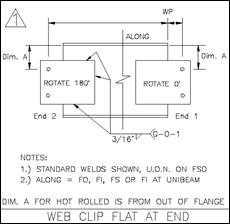

Plate Welded Flat on Web Extended Past End

1 or End 2

|

|

1. Use

the “Web

Clip Flat at End (WS-MC-09)” clip detail. 2. Insert

Clip with a Rotation of Rotate = 0 @ End 1 Rotate = 180 @ End 2 |