Secondary – Information

(Revised:

08/29/2024)

The Secondary Member

Information tab is used for the lap conditions and the connection criteria for

any secondary member.

The Continuous Lap Constraint

options are enabled when the member shape is a Zee, and the Member Type is set

to Continuous on the Description tab.

Continuous Lap

Constraints:

Lap Constraint - Dimension

From

this drop list, you may select the Secondary Lap Constraint Dimension desired;

the design will use the optimum lap required. The list contains the standard

lap dimensions that are available. This option is used in conjunction

with the Minimum and Hold radio buttons.

This

option is enabled when the member shape is a Zee and the Member Type is set to

Continuous on the Description tab.

„

Notes:

Short secondary members may be

automatically combined with an adjacent secondary, regardless of the lap

constraints.

Members in bays between 6’ and 12’ are

automatically made simple span and may not be lapped.

Lap Constraint - Minimum

The

Minimum Lap Constraint radio button sets the Lap Dimension selected as the

smallest lap that will be used during the secondary design process. This option is used in conjunction with the

Dimension drop list.

This

option is enabled when the member shape is a Zee and the Member Type is set to

Continuous on the Description tab.

„

Notes:

Short secondary members may be

automatically combined with an adjacent secondary, regardless of the lap

constraints.

Lap Constraint - Hold

The

Hold Lap Constraint radio button sets the Lap Dimension selected as the exact

lap that will be used during the secondary design process. This option is used in conjunction with the

Dimension drop list.

This

option is enabled when the member shape is a Zee and the Member Type is set to

Continuous on the Description tab.

„

Notes:

Short secondary members may be

automatically combined with an adjacent secondary, regardless of the lap

constraints.

Lap Option - High Strength

Bolts

The

High Strength Bolts check box for the Lap Constraint defines the Bolt type used

at the secondary-to-secondary connections at the ends of the lapped

members. High Strength Bolts are A325. Default is to always use High Strength Bolts

for secondary connections.

This

option is enabled when the member shape is a Zee and the Member Type is set to

Continuous on the Description tab.

Lap Option - Washers

Required

The

Washers Required check box for the Lap Constraint adds Washers to the Bolts and

Nuts at the secondary-to-secondary connections at the ends of the lapped

members.

This

option is enabled when the member shape is a Zee and the Member Type is set to

Continuous on the Description tab.

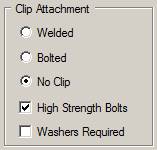

Clip

Attachments:

Clip Attachment Option -

Welded Clip

The

Welded clip radio button defines the type of clip(s) used for the secondary to

primary connection to be a shop Welded clip.

Clip Attachment Option -

Bolted Clip

The

Bolted clip radio button defines the type of clip(s) used for the secondary to

primary connection to be a field Bolted clip.

Manufacturing will punch the necessary holes in the primary frame.

„

Notes:

When clips are attached to flanges

thicker than 5/8” they will automatically be revised to a Welded clip. This will occur at

flange material that cannot be punched with a 9/16'' diameter punch.

Clip Attachment Option - No

Clip

The

No Clip radio button defines the secondary to connection directly to the

primary frame. This is the default

setting.

For

11.5” purlins, there will always be a clip provided. Additionally, a clip will be provided at

purlin strut locations and when purlin anchorage design requires an anti-roll

clip.

„

Notes:

Holes may not be used in flanges >

5/8” thick. They will automatically

detail a Welded clip at these locations.

Clip Attachment Option -

High Strength Bolts

The

High Strength Bolts check box for the Lap Constraint defines the Bolt type used

at the secondary to clip and the clip to primary frame connections (if

applicable).

Clip Attachment Option -

Washers Required

The

Washers Required check box for the Clip Attachment adds Washers to the Bolts

and Nuts at the secondary to clip and the clip to primary frame connections (if

applicable).

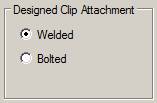

Designed Clip

Attachments:

Designed Clip Attachment

Option - Welded Clip

The

Welded clip radio button defines the type of designed clip(s) used for the

secondary to primary connection to be a shop Welded clip. Designed Welded Clips occur at purlin strut

lines and/or anti-roll purlin anchorage purlin strings.

Designed Clip Attachment

Option - Bolted Clip

The

Bolted clip radio button defines the type of designed clip(s) used for the

secondary to primary connection to be a field Bolted clip. Manufacturing will punch the necessary holes

in the primary frame. Designed Bolted

Clips occur at purlin strut lines and/or anti-roll purlin anchorage purlin

strings.

„

Notes:

The “Designed Clip Attachment” can only

be User selected when the above “Clip Attachment” selection is selected as “No

Clip”.

When clips are attached to flanges

thicker than 5/8” they will automatically be revised to a Welded clip. This will occur at

flange material that cannot be punched with a 9/16'' diameter punch.

Flange Brace:

Flange Brace - Available

This

button is the Auto Design system default and allows design to use a Flange

Brace at the secondary location to laterally support the Inside Flange of the

frame member.

Flange

Braces may or may not be required at this location(s), depending on the frame

design requirements.

Flange Brace - Not

Available

This

button flags the system to ignore this secondary location for Flange Bracing of

the frame member. The

result is that the Inside Flange of the frame will be designed as unsupported.

Flange

Braces will not be generated at this location(s) when the frame is designed.

There

are places on a frame where Flange Braces are ALWAYS required and this radio

button may not be used to remove those Flange Braces. Such locations are;

rafters over Interior Columns, rafters over endposts or Turned Interior

Columns, the last girt/purlin in haunches, and for all secondary locations on

Truss (VP Open Web) rafters.

Flange Brace - Must Use

The

Must Use radio button flags the system to ALWAYS generate a Flange Brace at

this secondary location.

This function has no control for flange bracing of

Truss (VP Open Web) rafters.

Standard

Controls:

See also: