Frames Segment Information

(Revised:

08/29/2024)

The frame

information window allows the user to modify data relating to frame members.

The types of modifications

allowed include, among others, holding a member straight and changing base

elevations.

Shape:

Member Type

This

is a non-changeable field defined by the members use in a frame line. For example, an

Exterior Column cannot be used as a Rafter.

Material Type

This

field is determined by the Member type. This is the type of material that will

be used to design and manufacture the member. For example, Endposts are typically

gage members but may be built up (three plate), rafters and members of primary

framing members are typically built up (three plate).

Material Shape

This

field is determined by the selection in the Material Type field.

For

example, Built Up is 3 Plate Built up, Gage is Back-to-Back or Single Cee, and

Hot Rolled is Tube at Exterior Columns (Tube, Pipe and Wide Flange at Endposts

or Interior Columns and Tube and Channels for Rafter Only type frames).

Geometry

This

field allows the user to change the standard geometrical configuration of a

frame member. For

example, you can hold a column straight; restrict depths at one or both ends.

End Options:

Depth

This

field allows user to restrict the frame member

geometry measured from outside of the flanges. Input is in feet/inches/sixteenths or

mm if metric. For

columns, End 1 is the base and End 2 is the haunch. For Rafters, End 1 is ALWAYS the high

end, and End 2 is the low end of the rafter.

None

This

is the default selection and allows system design to optimize depths as

required. Tapered

shapes are usually the most economical.

Hold

This

field allows the user to hold geometry depths of a member. When selected, the frame member will

be generated (designed and detailed) with the user-specified depth providing

the frame designed successfully.

For

example, if 18 is specified, this dimension will be

held even if 12 would be more economical.

Minimum

This

field allows the user to specify minimum geometry depths of a member.

When

selected, the Building Editor will start with the user-specified depth and

increase the depth if required.

Maximum

This

field allows the user to specify maximum geometry depths of a member.

When

selected, the frame will optimize depths up to the maximum depth but no deeper. The resulting depth

can be less than the Maximum value if generated by design optimization.

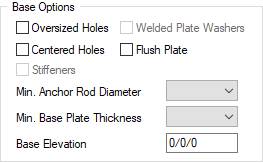

Base Options:

Oversized Holes

Checking

this box will allow the base plates to be detailed with a pre-determined hole

size of at least 5/16 larger than the Anchor Rod diameter. Note:

Standard sized holes are a minimum 1/8 larger than the Anchor Rod

diameter.

When

using oversized holes without welded washers, only two Anchor Rods will be used

to resist base shear loads even when more than two Anchor Rods are in the base

plate.

Welded Plate Washers

This

check box will be activated and may be selected only if the Oversized Holes box

is selected. However,

Welded Plate Washers are not required with Oversized Holes.

Using

this option along with Oversized Holes will allow all the Anchor Rods to resist

shear in the strong axis of the frame, and a maximum of four Anchor Rods will

be used to resist shear in the columns weak axis (bracing) direction. Anchor Rod bending

is considered with this option.

Centered Holes

This

check box will allow the user to select an Anchor Rod pattern that will be

centered in the depth of the column base.

The

software will not automatically make any of the column base depths the same

when this option is selected.

The user may enforce a column depth to ensure uniformity of

Anchor Rod placement.

When

using Pipe or Tube, the resulting base plates will be square. Rectangular plates are the default

when the Centered Holes option is not selected.

Flush Plate

Selecting

this box will make the outside edge of the column flange flush with the base

plate.

Stiffeners

This

box can only be selected per certain design specifications.

Min. Anchor Rod Diameter

Selecting

from this drop list will define the minimum Anchor Rod diameter requested for

design for the specified column being edited in the Frames Schedule.

Min. Base Plate Thickness

Selecting

from this drop list will define the minimum Base Plate Thickness requested for

design for the specified column being edited in the Frames Schedule.

Base Elevation

This

field changes the column base elevation. Input is in feet/ inches/ sixteenths

or mm for metric input.

Positive

dimensions are above finished floor, negative

dimensions are below finished floor.

For Wind Posts, the default is set 0/2/0 to

account for the typically needed grouted condition because Wind Posts have a

fixed base plate.

Brace Points:

Dont Flange Brace

Select

this radio button when secondary members are present on a frame member, but

flange braces are not permitted on the Inside Flange of the frame at these

secondary locations.

The

secondary members will still be used to provide lateral support for the Outside

Flange of the frame member.

Use

This

selection is the system default and results in designing the frame member using

the secondary location to brace the Outside Flange while adding flange braces

to the Inside Flange if required by optimization.

Unsupported

Select

this radio button when the frame member is to be unsupported (no flange braces

to support the Inside Flange and no Outside Flange support provided by the

secondary). This

option results in uneconomical frame designs. Typically used on a sidewall when

it is designed for future expansion with no covering or girts in the future.

Plate

Orientation (affects haunches only):

Top

This

radio button is the default and generates Top Bolted connections where the

Bolting Plate is horizontal to the ground. The system may override this selection

in certain cases where Face (or Vertical) Bolted haunches are required by

design, such as when Portal Braces are used.

Face

This

radio button makes the column bolting plate a Face connection. The Bolting Plate is perpendicular to

the roof slope.

Vertical

This

radio button makes the column bolting plate a Vertical connection.

Primary Offset:

Match Secondary Depth (outset)

When

selected, this option will hold the offset distance (distance from outside

secondary member to outside flange of the primary framing member) to match the

selected secondary member depth (7, 8½, 10 or 11½)

The

Secondary Offset to the Building Line Dimension can be adjusted in the

Secondary screens to recess the secondary and primary framing further into the

building.

A

positive dimension moves the secondary and primary into the building, a

negative dimension moves the secondary and primary frame outward from the

building.

Outside Flange

When

selected, this option will measure the input frame offset dimension from the outside

flange of the primary framing member to the Building Line. Any offset revision made at the

Secondary level will be overridden by this selection.

Offset Dimension

This

input field (feet/inches/sixteenths or mm with metric input) is used in

conjunction with the Outside Flange options to measure the distance from the

Building Line to outside flange of the primary framing member.

Use Offset from Secondary Information

When

selected, the Building Editor will use the offset dimension input on the

secondary windows to measure the distance from either the outside or centerline

of the secondary member to outside flange of the primary framing member.

Standard

Controls:

See also: