Crane Schedule - Specifications

(Revised: 02/04/2015)

The Crane Specifications tab defines the

weight, additional parameters, and clearances of the crane.

Most

of the data on this tab can be derived from the reference table by clicking on

the “Apply Crane Data” button in the Crane Information tab.

Options:

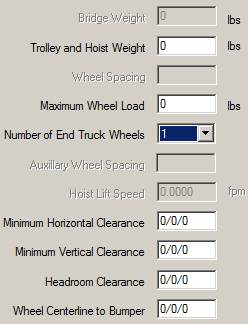

Bridge Weight

In

this edit box, enter the Bridge Weight.

Trolley and Hoist Weight

In

this edit box, enter the Trolley and Hoist Weight.

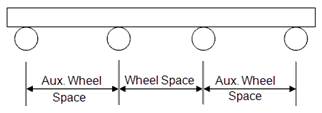

Wheel Spacing

In this edit box, enter the Wheel Spacing.

If the End Truck has two (2)

wheels, input the centerline distance between the wheels as shown.

If the end truck has four (4)

wheels, the Auxiliary Wheel Spacing field will become active, as shown in the

graphic above. Please refer to the “Auxiliary

Wheel Spacing” description below for a definition of this entry field.

When entering data for Monorail

cranes and when only 1 wheel is selected, the Wheel Spacing field will be

grayed out.

Maximum Wheel Load

In this edit box, enter the Maximum Wheel

Load. The entered value is applied

to each wheel location and should NOT include impact. The required Impact factor will be added

as required by the system when loads are applied to the brackets and frames.

If the end truck has four (4)

wheels, using the maximum wheel load can be conservative as often times the

wheel loads are not equal. If

possible, get specific crane information that includes the Wheel Spacing and

each of the Wheel Loads.

Number of End Truck Wheels

From

this drop list, select the Number of End Truck Wheels. The available options are one (1), two

(2) or four (4). The dropdown list

will show either one (1) or two (2) End Truck Wheels as an option when

inputting a Monorail crane.

Auxiliary Wheel Spacing

When

the Number of End Truck Wheels is set to four (4) this field will become active

and allow data to be entered by the user.

The Auxiliary Wheel Spacing and Wheel Space distances are shown below

for the four (4) End Truck Wheel option.

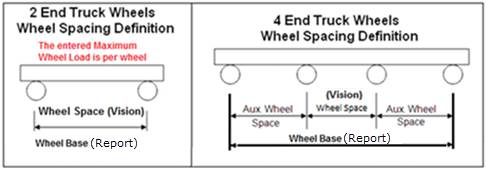

A

side-by-side comparison of 2 Wheel and 4 Wheel End Trucks is shown below:

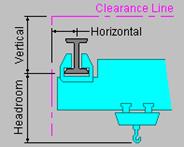

Minimum Horizontal Clearance

In

this edit box, enter the Minimum Horizontal Clearance from the crane beam or

rail centerline to the building column flange.

Minimum Vertical Clearance

In

this edit box, enter the Minimum Vertical Clearance from the top of rail or

bottom of Underhung/Monorail beam to the rafter bottom flange.

Headroom Clearance

In

this edit box, enter the Headroom Clearance from the rafter bottom flange to

the bottom of the hoist hook (when in the fully lifted condition).

Wheel Centerline to Bumper

In this edit box, enter the outermost Wheel

Centerline to Bumper.

This is used when you have two cranes in the

same aisle and this value is half of the distance that the two cranes can come

together as measured between the two cranes closest wheels.

Example:

Two cranes can be no closer than 2’-4” (centerline of each

cranes outermost wheel) so the Wheel Centerline to Bumper value entered should

be 1/2/0.

Standard

Controls:

See also:

§ Crane Schedule - Information