Secondary - Secondary Bracing

(Revised: 01/21/2021)

Secondary Bracing (8 1/2",

10", 11 1/2"):

|

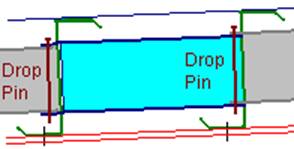

Typical

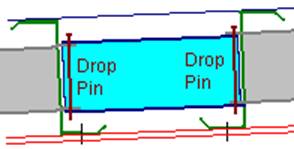

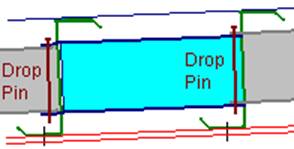

Roof and Wall Channel Brace Usage (Roof shown)

CPBA

CPBB

CPBC |

Mark Number = Length =

Drop Pin = Endcap = Secondary Limitations =

CPBA Maximum Length = CPBB Maximum Length = CPBC Minimum Length = CPBC Maximum Length = |

CPBA------ (ffiiss) - 0 Tabs CPBB------ (ffiiss) - 1 Tab CPBC------ (ffiiss) - 2 Tabs

8

1/2", 10", 11 1/2" Only 6

5/8" 12’-4

3/4" 10

3/8” 12’-6

5/8” |

|

Length calculation may produce a result slightly different

than Vision. Use Vision calculations for CPB_ length. |

||

|

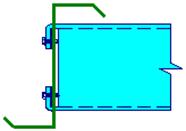

Typical PBA Usage (Roof Only)

Purlin Brace Assembly (BR09K8) Not at a Frame

Purlin Brace Assembly (BR09K2) At a Frame

Insulated Roof Panel Not at a Frame |

Mark Number = Length = Nuts = Fastener = Purlin Limitations = Minimum Length = Maximum Length = |

PBA---- (ffii) (Round

up to nearest inch) 47120

(2 per PBA) 097352

Scrubolt 097267

Scrubolt Nut 8

1/2", 10", 11 1/2" Only 1'-2" 5'-6" |

|

Length calculation may produce a result slightly different

than Vision. Use Vision calculations for PBA_ length. |

||

|

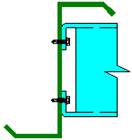

Channel Purlin Brace (BR09PK) Ridge |

Mark Number = Length = Drop Pin = Purlin Limitations = Minimum Length = Maximum Length = Maximum Roof Pitch = |

CPBR------- (pffiiss) Ridge

Purlin Space + 5" -

Rise of 1 1/2" at 8 1/2" -

Rise of 1 1/2" at 10" -

Rise of 3" at 11 1/2" (2)

097556 8

1/2", 10", 11 1/2" Only 8

1/2" 5'-5

3/4" 4:12

|

||||||||||||

|

High Slope Ridge Assembly

(BR09M9) Ridge |

Mark Number = 1/2" x 1 1/2"

A325 Bolts = Roof Pitch = |

HSRA-------(ccfiiss) (4)

49080 >

4:12 |

Typical Roof and Wall Channel Brace Connections

Channel Brace (BR09PH) Continuous

Channel Brace (BR09JG) Terminating (Channel Brace Lines Up With Slots in the Purlin/Girt Web)

Channel Brace (BR09JG) Terminating (Channel Brace Does Not Line Up with Slots in the Purlin/Girt Web)

Channel Brace (BR09JR) Terminating High Side

Channel Brace at Base (BRR008) |

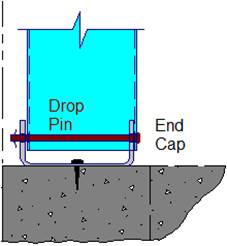

Drop Pin = Endcap = Fastener = |

55307 |

|

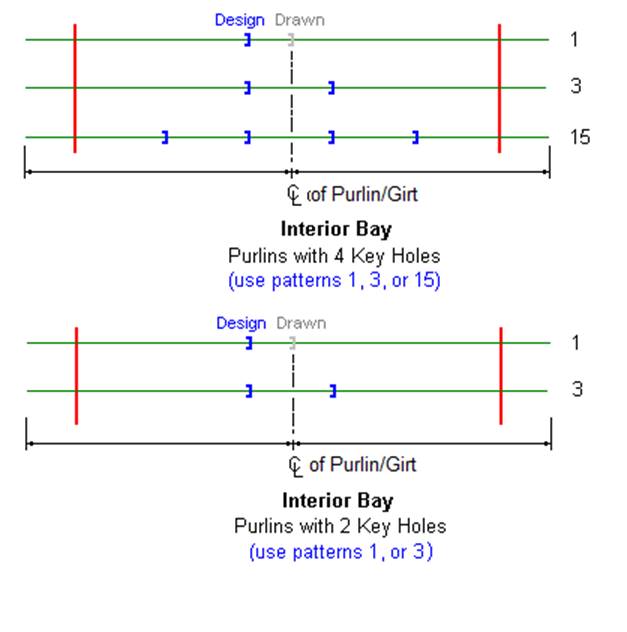

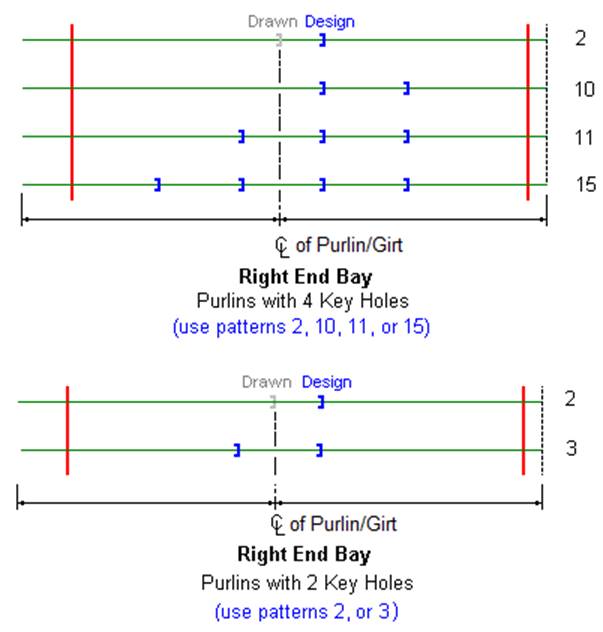

Roof Systems using an R Factor Design (Only

in Purlin Spaces required by Design)

|

Roof Systems using Discrete Bracing

----------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------

|

|

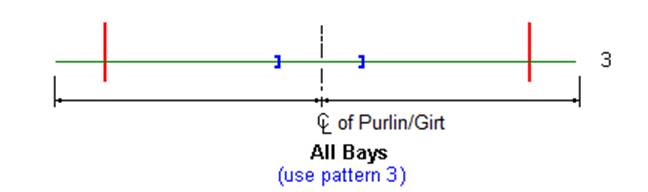

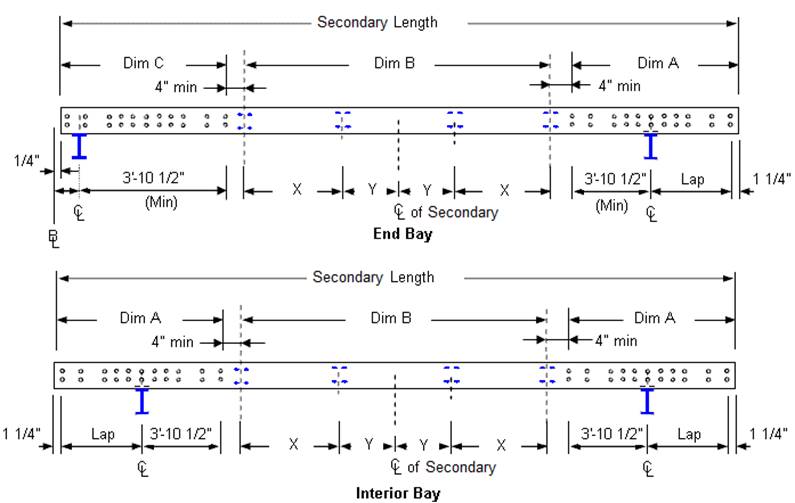

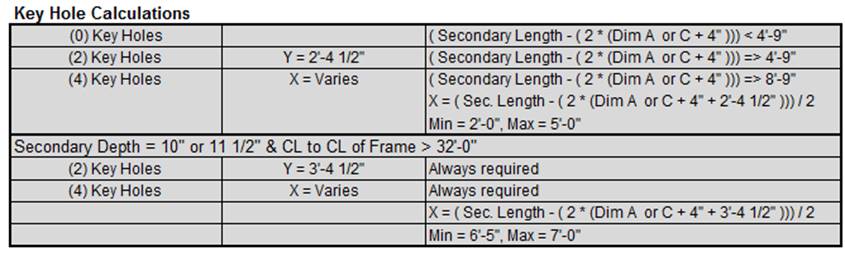

Key Hole Calculation

|

|

|

Note: Channel Purlin Bracing is not required if the

Corner Zone Jamb is within 18” of the Channel Purlin Bracing. |

|

Channel

Brace Rules:

|

|