Frames - Reverse

Taper Column (Fully Tapered Outside Flange)

(Revised:

04/01/08)

Input

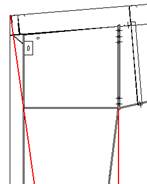

Setup BL to be the Roof Line.

Column Haunch depth should be held to the Haunch

Depth required at the Taper.

Hold Haunch Plate to Vertical.

Adjust FO Offset for Haunch Plate to be where the

Reversed FO will be.

Design

Design Column tapered at 80% Stress.

Detailing

Generate an FSD of the current Column to use as

Reference.

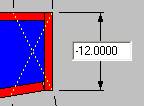

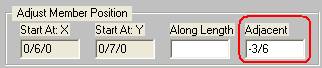

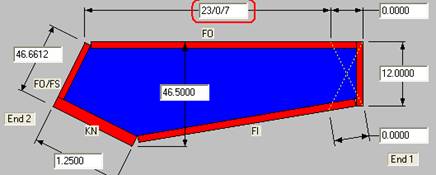

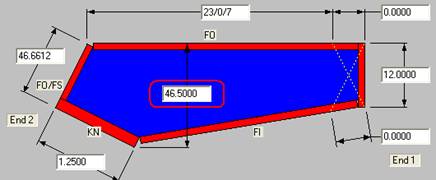

Revise End 1 Depth to a Negative Depth.

Adjust the Adjacent to move column FO into place.

![]()

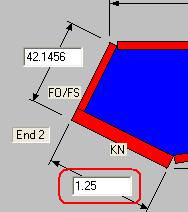

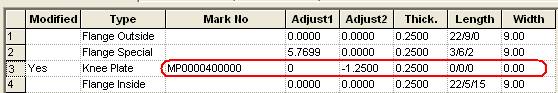

Change the Knee Depth to = FS thickness + 1”

(Save the Mark Number from the Haunch

Plate prior to revising Knee Depth)

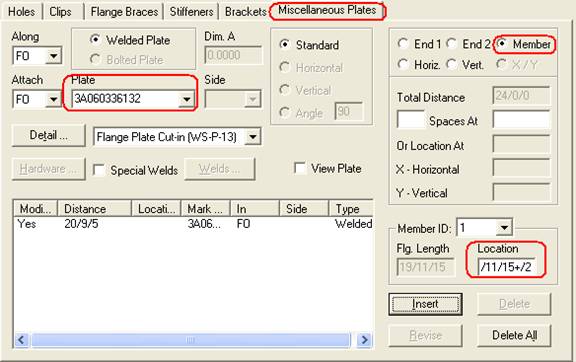

Revise the Haunch Plate to an MP Plate with the

same thickness as the Flanges.

Make the Width and Length = 0”.

This will need to be removed by PC on the Final

FSD’s.

(DO NOT TRY TO REMOVE THE KNEE PLATE)

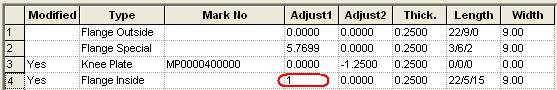

Revise Flange Inside Adjust 1 to = 1”

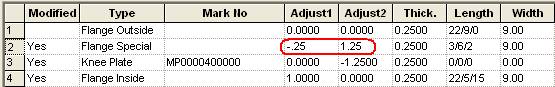

Revise Flange Special Adjust 2 to = Flange Inside Thickness + Rise of 1” + Req’d FS Extension.

Revise Flange Special Adjust 1 to = Negative the

Flange Outside Thickness.

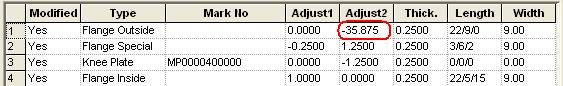

Revise Flange Outside Adjust 2 to = Negative the

(Cut In Plate Length – Flange Special Thickness).

Revise the Frame Member lengths as required.

Revise the Haunch Depth to generate the correct Taper

along the Flange Inside.

Insert Cut In plate matching the original Haunch

Plate along FO.

Insert along member at the Total FO length + Edge

Distance to Hole.

Add Welds to Cut In Plate

to match the original Haunch Plate.

Revise the S3 stiffener to an S2 stiffener. Swap

all FO & FI welds.

Swap all FO & FI welds on the Flange Special.

Check for any FO to Web welds on the original FSD.

Swap with FI as needed.

Modify the Base Plate as Needed.

Adjust the Rafter length to match the Cut In Plate.

Verify ALL Holes and Clips located along the Flange

Special.

Verify ALL Holes and Clips located along the

Column.

Adjust Near Side / Far

Side parts on the column.