Frame Data – Insertion of Type 8 Stiffeners

(Revised: 08/14/12)

This How-to will explain the insertion of type 8 stiffeners.

|

|

1. Before

starting to insert your Type 8 Stiffener, you need to note the Member #s that

the Splice Plate is attached to. |

|

|

|

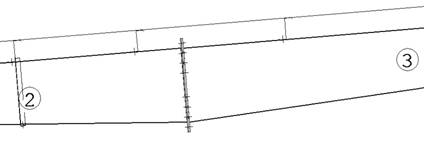

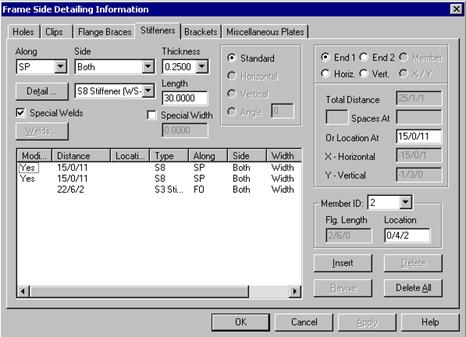

2. After

you have selected a member and picked the Properties button, choose the Stiffeners tab. Select the element Along as SP. 3. The

Detail S8 Stiffener will be selected

automatically, and is the only detail option for locating along an SP. |

|

|

|

Note: The location

of an S8 Stiffener is located from the outside of the FO to the Centerline of

the Stiffener. |

|

|

|

4. Next,

fill in the appropriate side, thickness, and length fields as required. 5. Special width-use this radio button to

activate the width field if required, otherwise the software will generate

the stiffener width based on ½ the splice pate width minus ½ clearance. 6. Special weld-use this radio button to

activate the Welds button, otherwise the shop will use standard welds based

on the manufacturing details. (Note: you must insert the stiffener into the

list and then re-select it before using special welds) |

|

|

|

7. Select

the Member ID that we had

noted at the beginning of the How To. 8. Insert

the Location from the Outside of the FO to the centerline of the S8 in the Member ID Location. 9. Insert

the Approximate Location of the Splice Plate from the Work Point in the Or Location At box |

|

|

|

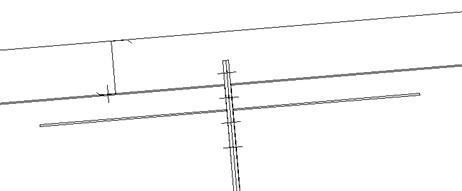

10. When

all required information has been input, pick the Insert button 11. View

the inserted part on the graphics screen to visually check what you have done

and/or Check the FSD. |

|